The standard dimensions of plywood typically measure 4 feet by 8 feet (48 inches by 96 inches), making it convenient for most construction and woodworking projects. Thickness can vary, with common options including 1/4 inch, 1/2 inch, and 3/4 inch, allowing you to select the most suitable size based on your specific needs. For example, 3/4-inch plywood is often used for flooring and cabinetry due to its strength and stability. Always check your project requirements and local supply, as specialty sizes and thicknesses may also be available at many lumberyards.

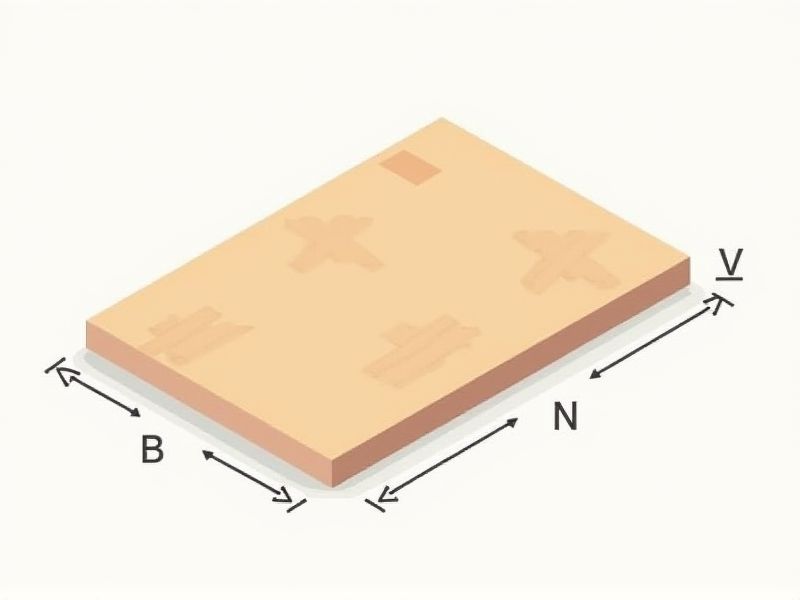

Width

Plywood typically adheres to industry-standard widths, which generally range from 4 feet to 5 feet (48 inches to 60 inches). In residential applications, sheets are often available in increments of 1/8 inch, with 1/2 inch and 3/4 inch being the most common thicknesses you will encounter. It's important to note that these sheet sizes facilitate easy handling and installation, especially in framing and sheathing projects. For specialty projects, some manufacturers offer custom widths tailored to meet specific design requirements, enhancing your options for unique space solutions.

Length

Plywood panels typically come in standard lengths of 4 feet (48 inches) or 8 feet (96 inches), with variations depending on specific applications. For construction and cabinetry, 4'x8' sheets are the most common size, catering to diverse projects and easing material handling. When selecting plywood, consider the length alongside its thickness, which usually ranges from 1/8 inch to 1 inch, to ensure it meets structural requirements. Proper length selection can optimize waste reduction and enhance your project's overall efficiency.

Thickness

Plywood thickness typically ranges from 1/8 inch to 1 inch, with 1/4 inch, 1/2 inch, and 3/4 inch being the most common sizes in residential and commercial applications. The thickness of plywood significantly affects its strength, durability, and overall performance, with thicker panels generally providing superior resistance to bending and warping. For structural projects, the American Plywood Association recommends minimum thicknesses based on specific applications, such as 5/8 inch for subflooring and 3/4 inch for sheathing. When selecting plywood for your project, consider the intended use and load-bearing requirements to ensure optimal performance and longevity.

Grade

Plywood is categorized into various grades, with "AA" being the highest quality, offering a smooth, sanded surface ideal for furniture and cabinetry. Grade "A" features a clean face with minimal repairs, suitable for applications where appearance is crucial. In contrast, Grade "B" includes small knots and blemishes, making it more appropriate for structural use or hidden applications. Understanding these grades helps you choose the right plywood for your specific project requirements, ensuring both aesthetic appeal and structural integrity.

Core Type

Core type plywood is categorized based on its internal structure, impacting strength, durability, and application suitability. Common core types include solid wood, particleboard, and medium-density fiberboard (MDF), with each offering unique advantages; for instance, plywood with a solid wood core exhibits superior strength and resistance to warping. Typically, plywood with a thickness ranging from 3mm to 25mm serves various construction and furniture projects, where you can expect a bending strength of roughly 20 to 40 MPa depending on the core material. When selecting core type plywood, consider its intended use, weight capacity, and environmental factors to ensure optimal performance.

Veneer Layers

Plywood is typically constructed from three to multiple veneer layers, with the most common configurations being 3, 5, or 7 layers, depending on the thickness and intended use of the panel. Each veneer layer, usually about 1.5 to 3 millimeters thick, is oriented perpendicularly to the adjacent layers, enhancing strength and stability while minimizing warping. The quality of the veneers can significantly impact the plywood's durability and appearance, with hardwood species like oak and birch offering superior characteristics compared to softer woods. When selecting plywood for your projects, consider grades that define the veneer quality, ranging from A (highest quality) to D (lower quality), ensuring you choose the right level for your specific application.

Finish

Plywood is categorized into various grades based on its finish, which significantly impacts its usability in construction and furniture. The highest quality plywood, classified as A-grade, features a smooth, defect-free surface ideal for visible applications, while B-grade plywood may contain slight imperfections but is still suitable for projects requiring a decent finish. C-grade plywood often has more knots and repairs, making it appropriate for unseen structural uses. Your choice of plywood finish can influence aesthetic appeal and durability, with options ranging from sleek veneers to robust laminates enhancing the overall look and performance of your project.

Moisture Resistance

Moisture resistance is a critical standard for plywood, particularly for applications in humid or wet environments. High-quality plywood typically has a moisture content below 10%, which minimizes the risk of warping or deterioration. Using a waterproof adhesive, such as phenolic resin, enhances the plywood's durability, making it suitable for exterior use and areas exposed to water. When selecting plywood, look for grades marked with 'MR' or 'moisture-resistant' to ensure it meets industry standards for moisture exposure.

Face Veneer Quality

Plywood standards emphasize the quality of face veneers, which significantly impact both aesthetic appeal and durability. High-quality face veneers often exhibit smooth surfaces, consistent grain patterns, and minimal defects, ensuring a more polished final product. According to industry specifications, the grade of face veneer is classified into several categories, with "A" denoting the highest quality, free from knots and imperfections. When choosing plywood, consider face veneer ratings as they directly correlate to the plywood's application, longevity, and overall value in your projects.

Weight

The standard weight of plywood typically ranges from 28 to 30 pounds per 4x8 foot sheet, depending on the thickness and type of wood used. For instance, a common 3/4-inch thick plywood made from softwood may weigh about 60 pounds, whereas a similar thickness made from hardwood could weigh significantly more, around 75 pounds. When choosing plywood for your project, consider that lighter options, such as those composed of thinner layers or manufactured with specific lightweight materials, can weigh as little as 22 pounds per sheet. This weight differential can impact handling, transportation, and overall structural integrity in various applications.