Understanding the standard dimensions of train tracks is essential for anyone working in railway design or maintenance. The most commonly used track gauge worldwide is the "standard gauge," which measures 1,435 millimeters (4 feet 8 1/2 inches) between the inside edges of the two rails. This gauge allows for interoperability of trains across many regions and countries, promoting efficient transport. Knowing these dimensions helps ensure compatibility with commonly used rolling stock and supports safer, more reliable railway operations.

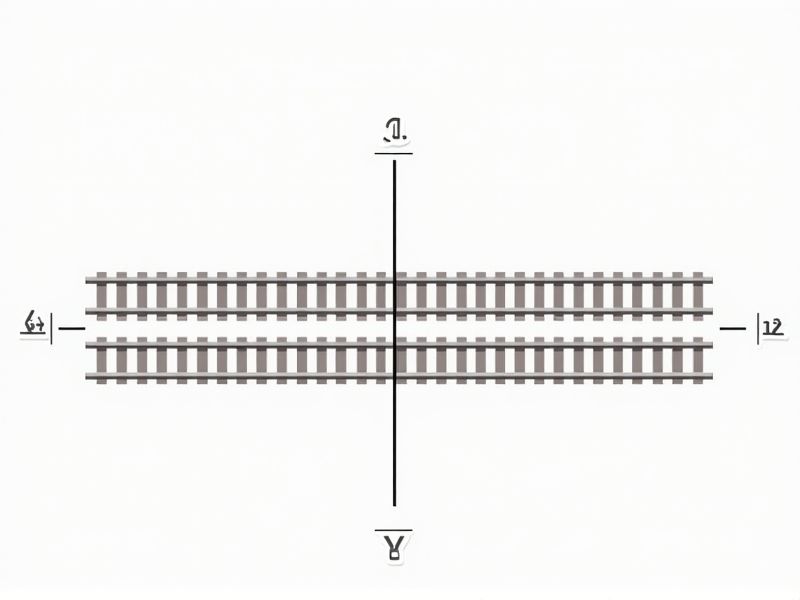

Gauge Width

The standard gauge width for train tracks measures 1,435 millimeters (4 feet 8.5 inches), which is the most widely used gauge worldwide, facilitating interoperability between various railway services. Narrow gauges, such as the 1,067 mm (3 feet 6 inches) gauge, are employed in specific regions to enhance economical construction and operational flexibility. In contrast, broad gauges, which typically exceed 1,600 mm (5 feet 3 inches), are utilized to allow for higher speeds and increased stability. Understanding gauge width is crucial for ensuring efficient rail transport systems and optimizing the movement of goods and passengers across different train networks.

Rail Height

The standard rail height for train tracks typically measures between 5 to 6 inches, depending on the specific type of railway system and the weight of the trains being supported. This critical dimension ensures proper alignment and stability, facilitating safe train operations over varying speeds and loads. Maintaining the optimal rail height is essential for reducing wear and enhancing the lifespan of both the tracks and rolling stock. Regular inspections and adjustments to your railway infrastructure can significantly improve overall safety and efficiency.

Sleeper Length

The standard sleeper length for railway tracks typically ranges from 2.4 meters (7.9 feet) to 3.3 meters (10.8 feet), depending on the specific track gauge and load requirements. Longer sleepers, such as those measuring 2.6 meters or more, provide enhanced stability and weight distribution, crucial for high-speed trains. Engineering studies highlight that a sleeper with a length of 2.5 meters can effectively support high axle loads, resulting in reduced track maintenance costs. Ensuring the right sleeper length is vital for maintaining both safety and efficiency across various rail networks.

Track Center Distance

The standard for track center distance in railways typically measures 4 feet 8.5 inches (1,435 mm) for standard gauge tracks, ensuring optimal alignment and stability. This crucial dimension allows for the efficient operation of trains while accommodating various rolling stock designs. In contrast, narrow gauges can range from 2 feet to 3 feet 6 inches, affecting the capacity and type of trains that can run on these tracks. For your railway projects, adhering to these specifications helps maintain safety and compatibility across different rail systems.

Ballast Depth

The standard ballast depth for train tracks is typically between 6 to 12 inches, providing essential support for the sleepers and track structure. This depth is crucial for efficient water drainage, reducing the risk of track destabilization due to excess moisture. Proper ballast depth also enhances overall stability, allowing for loads of up to 143 tons per car without compromising safety. For optimal performance, regular inspections should ensure that the ballast quality and depth meet the prescribed standards, safeguarding your investment in railway infrastructure.

Rail Profile

The rail profile is crucial in determining the load-bearing capacity and overall performance of train tracks, with standard profiles such as UIC 60 and UIC 54 widely used in the industry. A UIC 60 rail profile typically weighs 60 kg per meter, while the UIC 54 profile weighs 54 kg per meter, both engineered for optimal strength and durability under heavy traffic. The geometry of the rail profile includes key dimensions like head width, web thickness, and base width, which collectively impact stability, wear resistance, and alignment. For effective maintenance and safety, monitor the rail profile regularly to ensure it meets the standard requirements essential for high-speed rail operations.

Clearance Envelope

The Clearance Envelope on train tracks is crucial for ensuring safe operations, typically defined as the space required to accommodate rolling stock without any hazards. This envelope must account for various factors, including track curvature, elevation, and infrastructure such as platforms and signal equipment, usually requiring a minimum lateral clearance of 3.7 meters from the centerline of the track. Federal standards often dictate that the vertical clearance should be at least 5.2 meters above the rail for freight trains to avoid collision with overhead structures. Regular assessments and maintenance of this Clearance Envelope are essential to protect both train operations and surrounding infrastructure.

Tie Spacing

Tie spacing on standard train tracks typically ranges from 16 to 24 inches, significantly influencing track stability and train performance. Proper spacing ensures even weight distribution across the ties, which are usually made from wood or concrete and can weigh up to 200 pounds each. This configuration not only supports the rails but also absorbs vibrations, enhancing ride quality for passengers and cargo alike. Maintaining optimal tie spacing is crucial for safety, with the Federal Railroad Administration overseeing compliance to minimize derailments and enhance operational efficiency.

Track Bed Width

The standard track bed width for railways typically ranges from 2.44 meters to 3.6 meters, depending on the type of track and its intended use. A wider track bed provides greater stability and load distribution, vital for accommodating heavy freight trains, which can weigh up to 40 tons per axle. Proper engineering ensures that the track bed is designed to support speeds averaging 80 to 120 km/h for passenger services. Regular maintenance of the track bed is essential, as it directly affects train safety and performance, preventing derailments and ensuring smooth operations.

Cant (Superelevation)

Cant, or superelevation, is crucial for maintaining train safety and speed on curves, with typical values ranging from 1 to 7 degrees. This elevation allows trains to counteract lateral acceleration, enhancing passenger comfort while reducing the risk of derailment. In more technical terms, it compensates for centrifugal force, ensuring that a train traveling at 100 km/h can navigate a curve with a radius of 300 meters efficiently. For optimal performance, the cant must be precisely calculated based on factors like train speed, curve length, and track material, tailored to your specific rail system to maximize safety and speed.