Understanding the standard dimensions of a rail track is essential for ensuring compatibility and safety in rail transport systems. Typically, the most common standard gauge for railways worldwide is 1,435 millimeters (4 feet 8 1/2 inches) between the inner faces of the rails. Along with gauge, other key dimensions include rail height, width, and spacing of sleepers (ties), which are generally spaced 600 to 700 millimeters apart center-to-center for standard tracks. Being familiar with these measurements helps ensure smooth train operations and easy maintenance or replacement of track components.

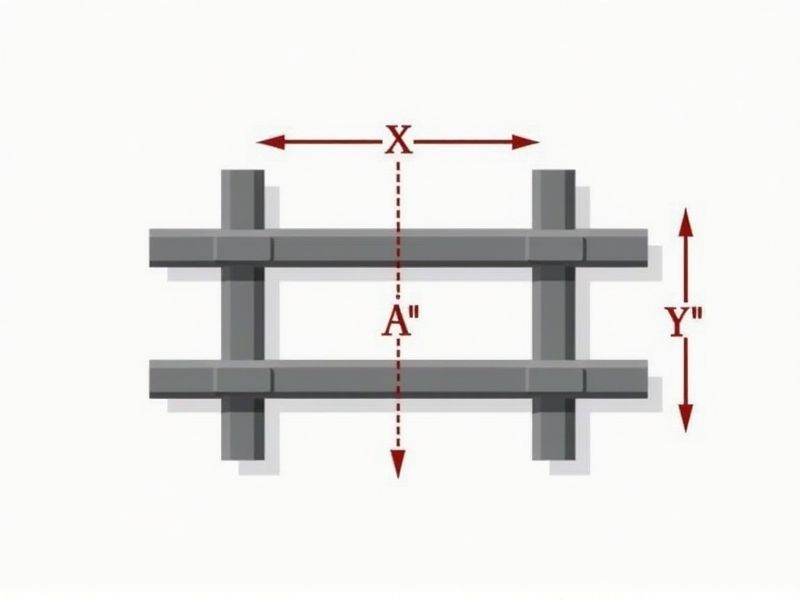

Gauge Width

Rail track standards primarily focus on gauge width, which is the distance between the inner edges of the rails. The most common gauge width, known as standard gauge, measures 1,435 mm (4 feet 8.5 inches) and is used in approximately 60% of the world's rail networks. Other gauges include broad gauge, typically ranging from 1,600 mm to 2,000 mm, and meter gauge, which is 1,000 mm. Precise gauge dimensions are crucial for ensuring interoperability between different rail systems and enhancing safety during rail operations.

Rail Profile

The standard rail profile, essential for optimal track performance, typically features dimensions such as a height of 140 mm and a base width of 150 mm, promoting stability under dynamic loads. This design ensures effective weight distribution, decreasing wear on both rails and rolling stock, which enhances safety and durability. Rail profiles are often categorized into various types, like the UIC 60, which weighs 60 kg per meter, commonly used for high-speed rail lines. You can improve track longevity by incorporating proper rail profiles tailored to specific operational conditions and traffic volumes.

Sleeper Spacing

Sleeper spacing is critical in maintaining rail track stability and safety, typically measuring between 18 to 24 inches apart, depending on the type of rail and expected load. Proper spacing ensures even distribution of weight and minimizes the risk of track deformation or failure under heavy loads, which can exceed 30 tons per axle. Rail operators often utilize concrete or wooden sleepers, each offering distinct advantages in terms of durability and cost-effectiveness. Adhering to specified sleeper spacing standards is essential for maximizing train speed and efficiency while reducing maintenance costs over time.

Rail Length

Rail track standards emphasize the importance of rail length, typically measuring between 39 to 80 feet for most configurations. Longer rails reduce the number of joints, minimizing maintenance costs while enhancing ride quality. In applications like high-speed rail, lengths of up to 200 meters (approximately 656 feet) are not uncommon, enabling smoother operations at speeds exceeding 300 km/h (about 186 mph). Your choice of rail length can significantly impact overall safety, efficiency, and longevity of the track system.

Track Bed Depth

The standard depth for a rail track bed typically ranges between 12 to 18 inches, depending on soil conditions and expected load requirements. A well-constructed track bed provides essential support, ensuring that the rails maintain proper alignment under the 20 to 30-ton weight of freight trains. Regular inspection is crucial, as even minor variations in depth can lead to track instability and increased maintenance costs, potentially reaching up to $1 million per mile annually. Investing in a high-quality track bed system can enhance safety and longevity, ultimately reducing the long-term operational expenses of your rail infrastructure.

Ballast Depth

The standard ballast depth for rail tracks typically ranges from 6 to 12 inches, depending on the type of railway and the loads it carries. A sufficient ballast depth is crucial for maintaining track stability, ensuring proper drainage, and distributing the weight of the trains to prevent deformation. Engineers recommend a minimum of 8 inches of ballast for heavy freight lines to support the significant load requirements. Insufficient ballast can lead to increased maintenance costs and decreased safety due to track shifting or misalignment.

Rail Joint Types

Rail joints are crucial components of rail track systems, ensuring the stability and integrity of the railway infrastructure. There are primarily two types of rail joints: welded joints and bolted joints. Welded joints, which can reduce maintenance and enhance smoothness, account for approximately 80% of modern rail systems, while bolted joints are more versatile and easier to replace, often used in areas requiring frequent adjustments. Implementing the appropriate joint type can significantly enhance the lifespan of rail tracks, typically ranging from 20 to 50 years depending on environmental conditions and maintenance practices.

Track Gradient

Track gradient is a critical parameter in rail infrastructure, typically expressed as a ratio of vertical rise to horizontal distance, such as 1:100 or 1:40. A standard track gradient for freight trains generally ranges from 1% to 2%, while passenger trains can operate efficiently on grades up to 4%. Your understanding of gradient impacts the locomotive's power requirements, where steeper gradients necessitate more powerful engines to maintain speed and efficiency. Properly managed track gradients enhance safety by minimizing the risk of derailments and ensuring smoother ride experiences for passengers.

Cant (Superelevation)

Cant, or superelevation, refers to the banking angle of a railway track at curves, designed to counteract the lateral forces acting on trains during transit. An optimal cant usually ranges between 1 inch for every 20 feet of track, ensuring that trains maintain speed and stability while navigating bends. This standard minimizes wear and tear on both the rolling stock and the infrastructure, enhancing safety by reducing the risk of derailment. You can improve ride quality and passenger comfort significantly by adhering to these cant guidelines in track design.

Rail Fastenings Configuration

Rail fastenings configuration plays a crucial role in maintaining the integrity and safety of rail tracks, impacting over 100 million rail journeys daily in the U.S. Various types of fastenings, such as elastic rail clips and screw spikes, ensure secure rail alignment and minimize track deformation under heavy loads. In 2021, rail fastening systems accounted for approximately 12% of total track maintenance costs, emphasizing their importance in the railway infrastructure. By optimizing fastening configurations, you can enhance the lifespan of tracks, reduce maintenance frequency, and improve overall efficiency in rail operations.