The standard dimensions of a pallet are typically 48 inches by 40 inches (1219 mm by 1016 mm) in North America, especially for the commonly used GMA (Grocery Manufacturers Association) pallet. This size is widely accepted because it fits well in most transport systems and maximizes cargo space. However, different industries and regions may utilize various pallet sizes; for example, in Europe, the standard Euro pallet measures 1200 mm by 800 mm (about 47.2 inches by 31.5 inches). When selecting pallets, always consider the compatibility with your racking systems and shipping requirements to ensure efficiency and safety.

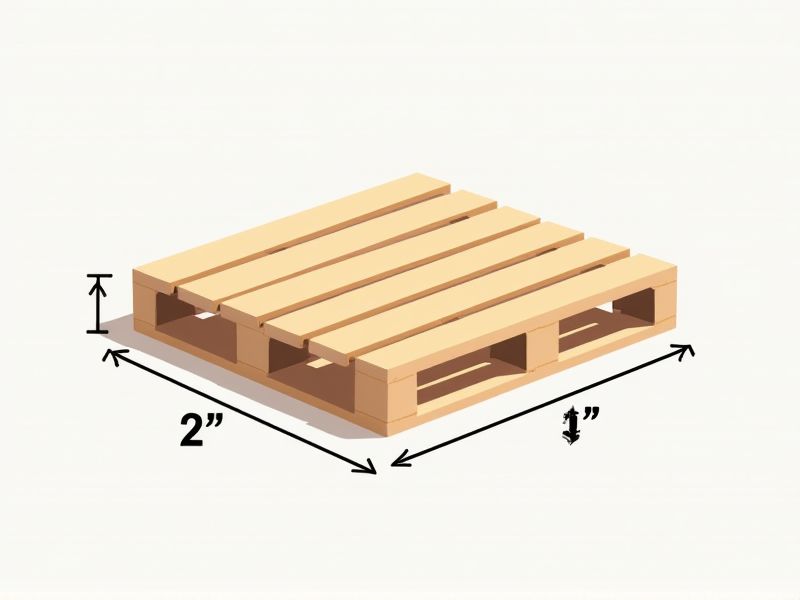

Size Specifications

The standard pallet size commonly used in North America is 48 inches by 40 inches, ideal for transporting goods efficiently. In Europe, the standard Euro pallet measures 1200 millimeters by 800 millimeters, facilitating compatibility with local shipping practices. Pallets typically have a maximum weight capacity of 2,500 to 3,000 pounds, ensuring safe handling of various products. Understanding these size specifications is crucial for optimizing storage solutions and logistics management in your supply chain.

Load Capacity

A standard pallet typically supports a load capacity ranging from 2,500 to 5,000 pounds, depending on the type and construction material used. For example, a common wooden pallet can handle up to 4,600 pounds when evenly distributed. This load capacity is crucial for optimizing warehouse space and ensuring safe transportation of goods. When selecting a pallet, consider not only the load capacity but also how it aligns with your specific storage and shipping requirements.

Material Type

The standard of pallets primarily revolves around the material type, significantly influencing their strength, durability, and overall performance in various applications. Wooden, plastic, and metal pallets are the most common types, with specific uses depending on the load requirements and environmental conditions. For instance, wooden pallets are widely used in the shipping industry due to their affordability and availability, while plastic pallets offer resistance to moisture and chemicals, making them ideal for food and pharmaceutical sectors. Understanding the material attributes allows you to select the right pallet type to enhance efficiency and safety in your supply chain operations.

Global Standards

The global standard for pallets is defined by the ISO 8611, which governs dimensions, weights, and material specifications to ensure consistency and safety in shipping. Most commonly, the standard size for a European pallet is 1200 mm x 800 mm, while the North American pallet typically measures 48 inches by 40 inches. Compliance with these standards facilitates efficient transportation and storage, minimizing the risk of damage during transit. Adhering to global pallet standards can enhance your supply chain efficiency, leading to cost savings and improved service delivery.

Regional Variations

Pallet standards vary significantly across regions due to differences in regulations, industry practices, and environmental considerations. In North America, the most widely used wooden pallet size is 48 x 40 inches, whereas Europe typically favors the 1200 x 800 mm (about 47 x 31 inches) format. Regional regulations, such as ISPM 15, mandate specific treatments for wooden pallets to prevent pest infestation, impacting pallet choice in international shipping. Understanding these regional variations is crucial for optimizing logistics, ensuring compliance, and improving supply chain efficiency.

Design Structure

The design structure of a standard pallet typically adheres to dimensions of 48 inches by 40 inches, conforming to the specifications set by the Grocery Manufacturers Association (GMA). This size allows for maximum efficiency in storage and transportation, accommodating varying loads up to 2,000 to 3,000 pounds. Made from materials like wood, plastic, or metal, the design not only ensures durability but also promotes ease of handling through forklift compatibility. Choosing the right pallet design enhances your supply chain efficiency by reducing shipping costs and improving inventory management.

Weight Distribution

The standard pallet design emphasizes optimal weight distribution to ensure stability and safety during storage and transport. Efficient load management typically entails a weight capacity of 1,500 to 2,500 kg, depending on the type of pallet. This strategic weight distribution minimizes the risk of tipping or collapsing, which can lead to product damage or workplace accidents. Industry regulations often mandate that pallets must facilitate even weight distribution to comply with safety standards and enhance operational efficiency.

Nesting Capabilities

Nesting capabilities of pallets significantly enhance storage efficiency and reduce your logistics costs by optimizing space utilization. When pallets are designed with nesting features, they can stack neatly within one another, minimizing the overall footprint by up to 50% when not in use. This clever design not only facilitates easier transport but also maximizes your warehouse capacity, allowing for greater inventory management. In industries such as retail and manufacturing, utilizing pallets with advanced nesting capabilities can lead to drastic savings in both time and resources.

Compliance Certifications

Compliance certifications for pallets are essential in ensuring that they meet regulatory standards for safety and quality. Key certifications include ISO 9001, which emphasizes quality management systems, and ISPM 15, which regulates wood packaging to prevent pest spread. In 2021, the global market for pallets reached approximately $60 billion, reflecting the growing demand for compliant and sustainable packaging solutions. When selecting pallets, consider their certifications to ensure they align with industry regulations and your operational needs.

Maintenance Requirements

The standard of pallets emphasizes stringent maintenance requirements to ensure safety and longevity. Regular inspections, at least once a month, help identify wear and potential damage, such as cracks, warping, or broken boards. Proper cleaning protocols, including pressure washing or steam cleaning, can prevent contamination, especially in food-grade applications. By adhering to these maintenance standards, you can extend the lifespan of your pallets and maintain compliance with industry regulations.