The standard dimensions for a long jump pit, as recommended by World Athletics, are typically 9 meters long and 2.75 meters wide. The pit should be filled with soft, damp sand and have a minimum depth of 0.3 meters to ensure athlete safety during landing. The takeoff board is usually placed 1 meter from the front edge of the pit, allowing athletes enough runway for their jump and safe clearance. Accurate long jump pit measurements help maintain fairness and consistency in competitions and provide a reliable training environment for athletes.

Length Of The Pit

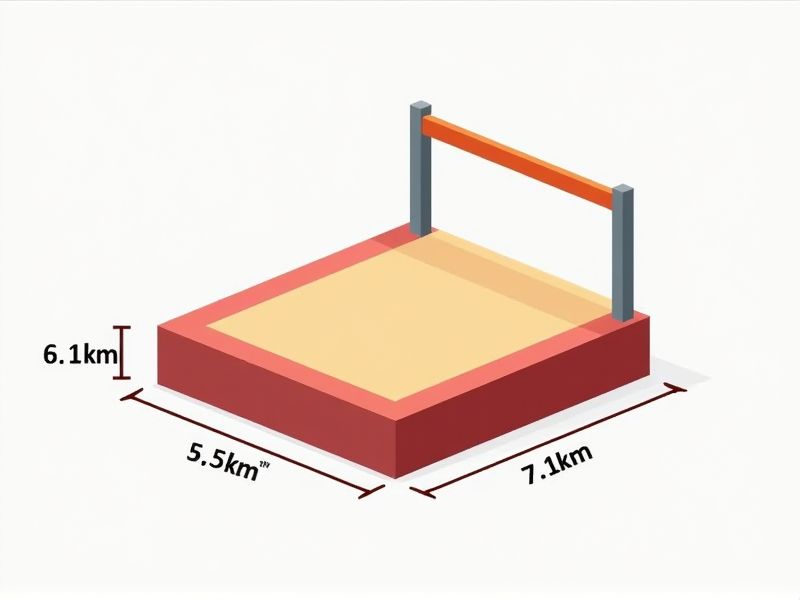

The standard length of a long jump pit is typically 2.75 meters (9 feet) for competitive events, ensuring adequate space for athletes to land safely. The width of the pit is generally 2.5 meters (8 feet), allowing for a uniform landing area regardless of the jump trajectory. Depth plays a crucial role as well, with a recommended minimum depth of 30 centimeters (1 foot) to absorb the impact and reduce injury risk. For optimal performance, make sure your jump pit complies with these specifications set by athletic federations.

Width Of The Pit

The standard width of a long jump pit is set at 2.75 meters, ensuring consistent jumping conditions across competitions. This measurement allows for athletes to execute their jumps safely and effectively while providing adequate space for landing. Proper maintenance of the pit's width is crucial to meet international regulations outlined by the World Athletics governing body. Ensuring your long jump pit meets these specifications can enhance both performance and safety for participants.

Depth Of The Sand

The standard depth of sand in a long jump pit must be at least 30 centimeters to provide adequate cushioning for athletes during landing. This depth helps to absorb the impact, reducing the risk of injury and ensuring a safer experience for competitors. A well-maintained pit should also be frequently raked and topped up to maintain consistency, as fluctuations in depth can affect jump performance. You should ensure that the sand is clean and free of debris, as this improves the safety and effectiveness of the jumping surface.

Runway Length

The standard runway length for a long jump pit is typically 40 meters, providing adequate space for athletes to achieve maximum speed before takeoff. A minimum width of 1.22 meters ensures a safe and effective transition to the jump area. The surface of the runway should be composed of materials like synthetic track or a similar high-friction surface to enhance grip and reduce the risk of slipping. Proper maintenance of the runway, including regular checks for wear and tear, is crucial to uphold safety and performance standards in competitive events.

Runway Width

The standard long jump runway width is 1.22 meters (4 feet), ensuring athletes have a consistent and safe area for approach. This uniformity is crucial for maintaining optimal speed and momentum leading up to the jump. A well-prepared runway can significantly impact your performance, affecting both your take-off and landing. Proper maintenance of this 1.22-meter width is essential for competitive events, as even minor deviations can alter jump dynamics.

Takeoff Board Placement

The takeoff board for a long jump pit is typically placed 1.21 meters from the foul line, ensuring athletes achieve an optimal jump distance. Heightening the takeoff board can significantly influence performance, with an ideal height ranging between 20 to 30 centimeters above the surface. Proper placement reduces the risk of fouls and enhances the athlete's jump technique, ensuring a smoother transition into the sand pit. Regular assessments of the takeoff board's condition and positioning can lead to improved results in competitive settings.

Safety Borders

The long jump pit must adhere to specific safety standards to ensure athletes' protection during competitions, featuring a minimum width of 2.75 meters. The safety borders surrounding the pit typically extend at least 1 meter away from the jump area, effectively cushioning any missteps or falls. Each pit should be equipped with a depth of at least 0.6 meters of sand to minimize injury risk upon landing. Your awareness of these safety guidelines is crucial for creating a secure environment for all participants.

Sand Type

The long jump pit should ideally contain high-quality silica sand, with a particle size ranging between 0.2 mm and 6 mm for optimal performance. According to athletics standards, the pit must be at least 9 meters in length and 2.75 meters in width, ensuring adequate space for jumpers to land safely. Proper maintenance of the sand, which generally weighs around 2,500 kg per cubic meter, is crucial to prevent compaction and maintain performance consistency. For a safe and competitive environment, the sand depth should be maintained between 30 cm and 40 cm, allowing for effective absorption of impact during landings.

Drainage System

An effective drainage system for a long jump pit is essential to maintain optimal performance conditions, preventing water accumulation that can affect jumping surfaces. Typically, a well-designed pit should have a slope of at least 1% to ensure efficient water runoff, with perforated drainage pipes placed every 3 to 5 meters to facilitate rapid drainage. The use of high-quality drainage materials, such as crushed stone or gravel, can enhance the longevity of the pit by allowing air circulation and preventing root growth. Implementing these standards not only improves safety for athletes but also extends the life of the jumping surface, ensuring consistent competition conditions.

Pit Edging Materials

The long jump pit's edging materials are crucial for ensuring safety and performance. Typically, materials like rubber or aluminum are used, with rubber providing shock absorption and aluminum offering structural integrity; both should comply with regulations to maintain a 2-meter width for the landing area. Your choice of edging can impact the durability of the pit, with high-quality options lasting up to 10 years under routine practice conditions. Regular inspection and maintenance of the edging can prevent damage and preserve the overall standard of the facility.