Elevator shaft dimensions can vary depending on the type, capacity, and manufacturer of the elevator, but there are industry standards that provide useful guidelines. For example, a typical passenger elevator serving 4-8 people usually requires a shaft measuring about 2000 mm (width) by 1500 mm (depth) (approximately 6'7" x 5') for an overhead traction system. It's important to consult with both your local building codes and elevator supplier, as requirements may change for accessibility, fire safety, or intended use (such as a freight elevator needing a larger shaft). Always ensure there is adequate space for both the cab and necessary clearance, and leave room for future maintenance access.

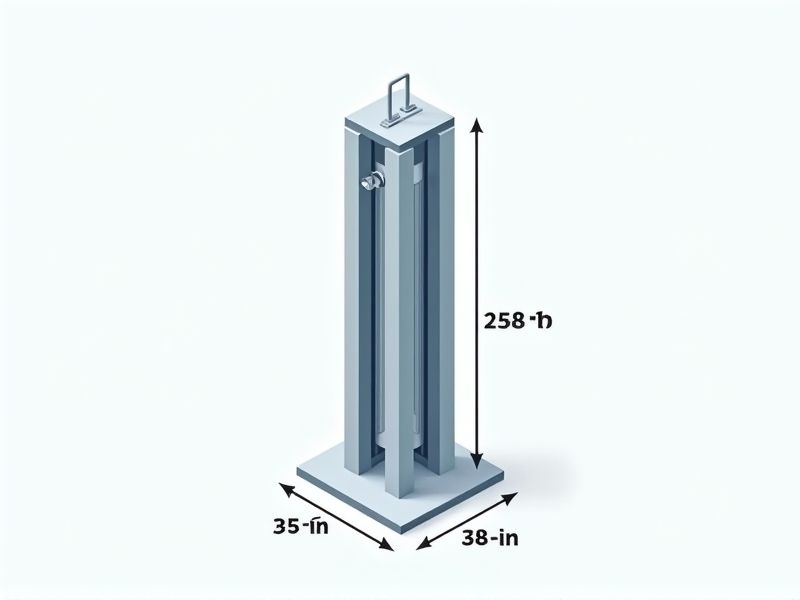

Shaft Width

The standard width of elevator shafts varies, typically ranging from 4 to 6 feet, depending on the type of elevator being installed. This measurement is crucial for ensuring adequate space for both the elevator car and any necessary mechanical components. Compliance with the Americans with Disabilities Act (ADA) often dictates these dimensions, as a wider shaft can facilitate access for all users. For your construction project, verifying local codes will ensure that the elevator shaft meets both safety and accessibility requirements.

Shaft Depth

The standard elevator shaft depth typically ranges from 4 to 6 feet, which ensures safe clearance for the elevator car and cables. In residential buildings, a minimum depth of 5 feet is often recommended to accommodate various elevator systems. For commercial applications, deeper shafts, up to 8 feet, may be necessary to accommodate larger, heavier elevators and their mechanical components. Understanding these dimensional requirements can help you plan for optimal installation and maintenance of your vertical transportation systems.

Clear Opening Width

Clear opening width in elevator shafts is essential for compliance and accessibility standards, typically measuring at least 36 inches to accommodate wheelchair access. This width ensures safe entry and exit for all users, including those with mobility aids. Adhering to this dimension not only meets regulations but enhances user experience in multi-story buildings. Ensuring optimal clear opening width can significantly reduce congestion and improve operational efficiency in vertical transportation systems.

Clear Opening Height

The standard for elevator shaft design emphasizes a minimum Clear Opening Height of 80 inches to ensure safe and convenient access for users. This measurement accommodates most individuals, including those in wheelchairs, enhancing accessibility in commercial and residential buildings. Compliance with local building codes typically requires that your elevator system maintain this height to fulfill ADA (Americans with Disabilities Act) requirements. Properly adhering to this standard can significantly improve user experience and ensure regulatory compliance during inspections.

Pit Depth

The pit depth for elevator shafts typically ranges from 3 to 5 feet, depending on the type of elevator system installed. The depth is crucial for ensuring proper clearance for the elevator car and for accommodating safety equipment such as buffers. Standard regulations also dictate that the pit must be constructed with a solid and stable base to support the weight of the elevator and any potential overloads. Ensuring your elevator shaft meets these pit depth requirements not only enhances safety but also contributes to the longevity and efficiency of the elevator system.

Overhead Clearance

Elevator shaft design mandates a minimum overhead clearance of 13 feet to ensure smooth operation and compliance with safety regulations. Proper overhead clearance is crucial for accommodating machinery and counterweights, while also preventing potential obstructions and allowing for maintenance access. Consider that your shaft should also account for additional headroom to facilitate emergency situations and inspections. Adhering to these standards not only promotes functionality but also enhances building safety and efficiency.

Guide Rail Distance

The standard for elevator shaft design emphasizes a guide rail distance of approximately 40 to 50 millimeters for optimal safety and performance. This spacing ensures smooth operation and minimizes vibrations during the elevator's ascent and descent. Maintaining a precise guide rail distance is essential to comply with safety regulations and enhance passenger comfort. Regular inspections and adjustments are recommended to ensure that your elevator system consistently meets these specifications.

Car Dimensions

Elevator shaft standards specify that car dimensions should typically range from 48 to 60 inches in width and 72 to 96 inches in depth to accommodate various passenger capacities. A minimum clear opening height of 80 inches is required to ensure safe and easy access for users. Compliance with the Americans with Disabilities Act (ADA) mandates that at least one elevator in multi-story buildings have a car capable of carrying a wheelchair, which necessitates a weight capacity of at least 2,500 pounds. Regular inspections and adherence to these dimensions are crucial for maintaining safety and efficiency in vertical transportation systems.

Door Type

Elevator shaft standards emphasize the importance of door types, which play a crucial role in safety and operational efficiency. There are two primary door types: single-panel and two-panel, both of which must adhere to specific building codes and regulations. For example, ANSI A17.1 mandates that elevator doors should have minimum dimensions of 36 inches in width to ensure accessibility for all users. Your choice of door type can significantly impact the flow of traffic and compliance with safety standards in multi-story buildings.

Load Capacity

Elevator shafts are engineered with a critical focus on load capacity, which significantly determines the performance and safety of vertical transport systems. A typical commercial elevator can handle loads ranging from 1,000 to 5,000 pounds, accommodating various passenger and cargo combinations. To ensure efficiency, the shaft's dimensions must align with the rated load, often requiring a minimum width of 5 feet and depth of 6 feet. Compliance with safety standards such as ASME A17.1 is essential for maintaining structural integrity and operational reliability, ensuring that your elevator performs optimally under maximum load conditions.