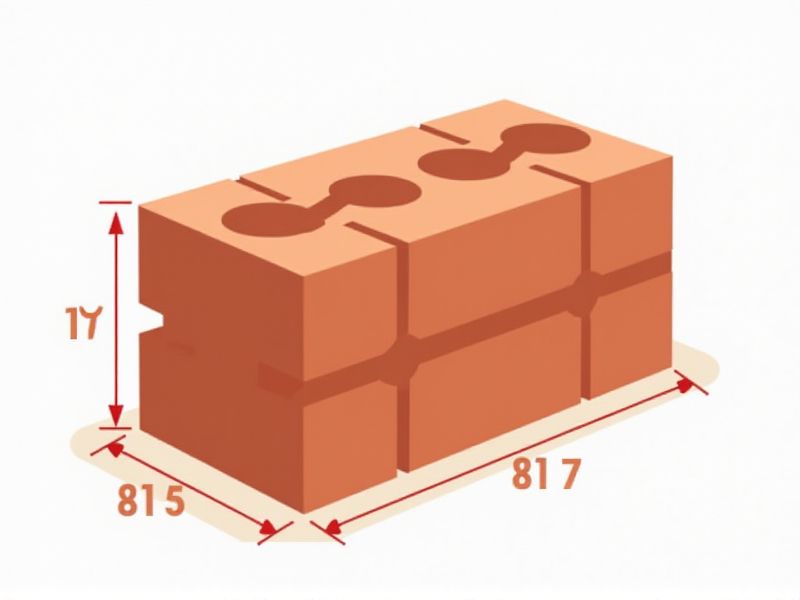

When selecting construction bricks, knowing their standard dimensions ensures your project will align with local building practices and material compatibility. In many countries, including the US, a standard brick typically measures 190 mm x 90 mm x 90 mm (length x width x height), but with mortar joints, the nominal size becomes 200 mm x 100 mm x 100 mm. In the UK and some other regions, standard bricks often measure 215 mm x 102.5 mm x 65 mm. Always check local building codes and supplier catalogs for the exact dimensions required in your area to avoid sizing issues during construction.

Consistent Masonry Patterns

Consistent masonry patterns in construction bricks enhance structural integrity and aesthetic appeal, with standards mandating a minimum compressive strength of 3,000 psi. These patterns not only improve load distribution but also contribute to better thermal insulation, reducing energy consumption by up to 30%. Your choice of bricks, typically measuring 7.5 x 3.5 x 2.25 inches, should ensure compatibility with local building codes. Adhering to these masonry patterns can significantly impact the durability and longevity of brick structures.

Structural Stability

Construction bricks must meet specific standards to ensure structural stability, usually defined by the American Society for Testing and Materials (ASTM). For residential or commercial buildings, bricks should have a compressive strength of at least 2,000 psi to adequately support loads. The water absorption rate is also critical, ideally not exceeding 15% to minimize the risk of moisture-related damage. When selecting bricks for your project, consider the durability ratings, as higher-rated bricks can last upwards of 100 years with proper maintenance.

Efficient Material Usage

The standard for construction bricks emphasizes efficient material usage, targeting a compressive strength of at least 3,000 psi for durability. Utilizing advanced manufacturing techniques, modern bricks incorporate recycled materials, reducing environmental impact by up to 30%. Each standard brick typically measures 7.5 inches long, 3.5 inches high, and 2.25 inches wide, allowing for optimal thermal insulation and energy efficiency in buildings. Ensuring minimal wastage during production not only conserves resources but also lowers overall construction costs, enhancing the sustainability of your project.

Construction Uniformity

The standard dimensions for construction bricks typically measure 7.5 inches long, 3.5 inches wide, and 2.25 inches high, ensuring uniformity across building projects. This consistency allows for efficient stacking, reducing gaps and improving thermal insulation. A well-maintained standard enhances structural integrity; bricks meeting these criteria can withstand compressive strengths of over 3,000 psi. By prioritizing these standards, you're contributing to a more durable and reliable construction outcome.

Cost Estimation Accuracy

The standard cost estimation for construction bricks typically ranges from $200 to $500 per thousand units, depending on material quality and regional market fluctuations. Accurate estimations are crucial, as a 10% variance can lead to significant budget overruns in large projects. Utilizing advanced software tools can enhance accuracy, reducing manual errors by up to 50%. When planning, always consider the long-term durability and sustainability of bricks, which can affect your overall investment and maintenance costs.

Standardized Tooling

Standardized tooling in the construction brick industry enhances efficiency and precision during manufacturing processes. By utilizing specific molds and automation, companies can produce up to 10,000 bricks per hour, ensuring uniformity in size and composition. This approach not only reduces waste but also meets industry regulations and quality standards, such as ASTM and ISO certifications. Your construction projects benefit from greater reliability and consistency in brick quality, promoting faster build times and reduced labor costs.

Aesthetic Appeal

The aesthetic appeal of construction bricks is vital for both residential and commercial projects, as it contributes to the overall visual harmony of buildings. Standard bricks are often available in various colors, sizes, and textures, allowing architects and builders to create unique designs that reflect the style of the area. Depending on the project requirements, you can select from options like traditional red, modern gray, or even textured finishes for added character. High-quality bricks not only enhance the appearance of structures but also offer durability and sustainability, making them a popular choice in contemporary architecture.

Optimal Load Bearing

The optimal load-bearing capacity of construction bricks is crucial for ensuring structural integrity in building projects. Standard bricks typically have a compressive strength ranging from 3,000 to 4,000 psi, enabling them to support significant weight without compromising safety. Utilizing bricks with uniform density and size can enhance their performance, contributing to a more stable foundation. When selecting bricks, it is essential to consider factors like moisture resistance and thermal insulation to meet the specific demands of your construction requirements.

Time-Efficient Construction

The standard of construction bricks significantly impacts time-efficient construction, with high-strength options reducing the need for extensive curing times. Utilizing modular bricks can speed up the assembly process, allowing for quicker project completions, potentially reducing labor costs by up to 25%. Implementing innovative interlocking designs can further minimize the use of mortar, enhancing structural integrity while saving valuable time during installation. Your choice of material and design can ultimately streamline construction timelines and improve overall project efficiency.

Reduced Material Wastage

Reducing material wastage in construction brick production can lead to significant cost savings and environmental benefits. By implementing efficient manufacturing processes, builders can minimize the average wastage rate, which typically hovers around 10%. Utilizing advanced technologies such as machine learning and automated quality control ensures that each brick meets specific standards while maximizing the use of raw materials. You can enhance sustainability in your projects by selecting bricks produced from recycled materials, achieving up to 30% reduction in waste during the manufacturing phase.