Standard dimensions of building blocks can vary by region and purpose, but commonly used sizes help ensure consistency and ease of construction. For example, a typical concrete building block (commonly called a concrete masonry unit or CMU) often measures 400 mm x 200 mm x 200 mm (length x height x width) in many countries. These dimensions make it straightforward to plan construction layouts, estimate material needs, and speed up the building process. Always check local building codes, as dimensions can differ slightly to accommodate regional standards and construction practices.

Size Uniformity

Size uniformity in building blocks significantly impacts construction quality and efficiency. Uniform dimensions, typically around 8 inches by 8 inches by 16 inches for concrete blocks, ensure precise alignment and reduce the need for extensive adjustments during assembly. This consistency minimizes construction waste, enhancing material utilization by up to 20%. By prioritizing size uniformity, you can achieve a sturdier structure and streamline the overall building process.

Load-Bearing Capacity

Load-bearing capacity is a crucial standard for building blocks, determining how much weight a block can support without failure. For instance, concrete blocks typically have a compressive strength ranging from 1,500 to 3,500 psi (pounds per square inch), making them suitable for various construction needs. When selecting building materials, considering the load-bearing capacity ensures the structural integrity of walls and foundations, which directly affects overall safety and durability. By understanding these specifications, you can make informed choices for your construction projects.

Thermal Insulation

Building blocks with a focus on thermal insulation significantly enhance energy efficiency in homes and commercial structures. A high R-value, often ranging from 20 to 40, indicates the material's effectiveness in resisting heat transfer. Utilizing insulated concrete forms (ICFs) can reduce heating and cooling costs by up to 50%. For your construction projects, selecting materials with superior thermal insulation properties is crucial for optimizing comfort and energy savings.

Acoustic Properties

Acoustic properties of building blocks, essential for sound insulation and noise reduction, should meet specific standards to enhance comfort in residential and commercial spaces. Materials with a Sound Transmission Class (STC) rating of 50 or above are recommended to effectively minimize sound passing through walls, floors, and ceilings. Utilizing dense materials such as concrete or specially formulated acoustic blocks can significantly improve these properties and contribute to an overall quieter environment. You should consider incorporating these standards into your construction projects to optimize acoustic performance and enhance the quality of your living or working spaces.

Water Absorption Rate

The water absorption rate of building blocks is a critical parameter, often expressed as a percentage, indicating the amount of water a block can absorb relative to its dry weight. For standard concrete blocks, this rate typically ranges between 5% to 15%, with lower rates signifying better durability and resistance to moisture-related issues. You should consider that a lower water absorption rate can enhance the energy efficiency of your structure, as it reduces the risk of thermal bridging. Testing the water absorption rate before procurement ensures that the building materials meet your project's specific requirements and longevity expectations.

Fire Resistance

Fire resistance is a crucial standard for building blocks, typically measured by classifications such as ASTM E119, which assesses the materials' ability to withstand high temperatures. High-density concrete blocks can achieve ratings of up to four hours of fire resistance, ensuring structural integrity during exposure to flames. Incorporating additives like fiberglass can enhance the fireproof qualities of these blocks, making them suitable for commercial buildings that require stringent safety measures. For your construction projects, selecting fire-resistant building blocks is essential to comply with local regulations and ensure occupant safety.

Compressive Strength

Compressive strength is a critical property of building blocks, typically measured in megapascals (MPa), which indicates their ability to withstand axial loads without failure. For instance, concrete building blocks generally exhibit compressive strengths ranging from 10 MPa to over 60 MPa, depending on the mix and curing process. This ensures structural integrity, especially in load-bearing applications, where blocks must endure significant weight and pressure. Your selection of building blocks with adequate compressive strength can greatly affect the longevity and safety of your construction project.

Durability

The standard of building blocks emphasizes durability, ensuring structures can withstand environmental stresses over time. With a compressive strength of up to 4,000 psi, concrete blocks provide a robust solution for both residential and commercial construction. Manufacturers often incorporate reinforced steel within the blocks, enhancing resilience against seismic activity and harsh weather conditions. Investing in high-quality building blocks can significantly reduce maintenance costs and extend the lifespan of your structures.

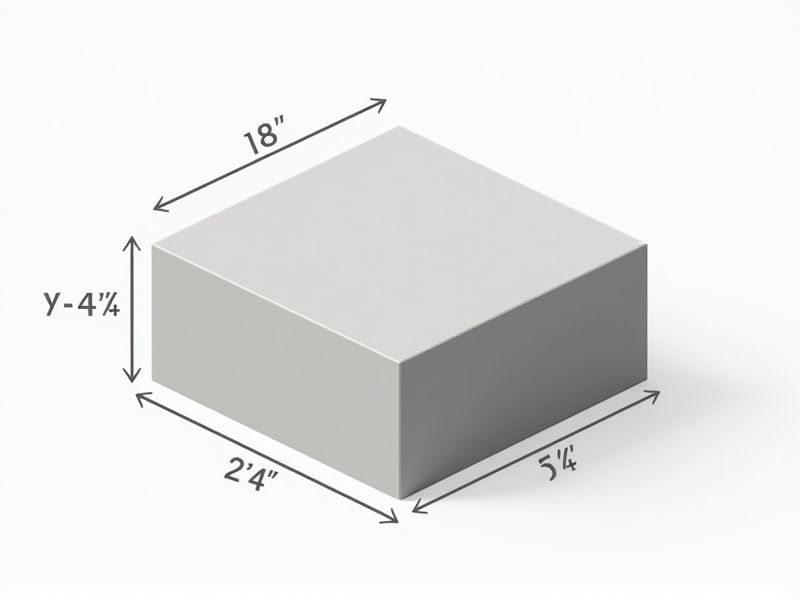

Dimensional Tolerance

Dimensional tolerance in building blocks is crucial, ensuring that each block conforms to specific measurements for optimal fit and function. Industry standards typically dictate tolerances within a range of +-0.5 mm, which is essential for maintaining structural integrity and stability. In the case of concrete blocks, a typical dimension might be 400 mm x 200 mm x 200 mm, necessitating accurate tolerances to prevent misalignment during construction. Proper adherence to these dimensional tolerances allows you to achieve efficient construction processes and a durable finished product.

Material Composition

The standard for building blocks emphasizes material composition, specifically requiring a minimum of 70% recycled materials to enhance sustainability. High-density polyethylene (HDPE) is commonly utilized due to its durability and resistance to environmental stress, with a lifespan exceeding 50 years. Compliance with ASTM and ISO standards ensures that materials meet safety and performance guidelines, reducing structural failures. Knowing the specifications can help you make informed choices when selecting building blocks for construction or renovation projects.