Understanding the standard dimensions of bricks is essential for efficient construction planning and material estimation. In many countries, the most commonly used standard brick size is 190 mm x 90 mm x 90 mm (length x width x height), with a nominal size including mortar joints being 200 mm x 100 mm x 100 mm. Using standardized brick sizes helps ensure structural stability and simplifies calculations for quantities and layout. Always check local building codes, as dimensions may vary slightly based on regional practices or project requirements.

Consistency In Construction

The standard of brick in construction requires strict consistency to ensure structural integrity and uniform appearance. High-quality bricks typically adhere to the dimensions of 7.5 x 10.5 x 22.5 cm, allowing for precise stacking and bonding. Consistent compressive strength, typically ranging from 7.5 to 10 MPa, contributes to the durability and longevity of masonry structures. By prioritizing consistency in brick construction, you can enhance the overall performance and aesthetic appeal of your building projects.

Structural Stability

The standard of brick primarily addresses key aspects of structural stability, particularly through its compressive strength, which typically ranges from 3,000 to 5,000 psi. Brick density, commonly around 1,200 to 1,900 kg/m3, influences its durability and resistance to cracking and deformation. Proper curing processes and adherence to fire resistance ratings ensure that bricks contribute robustly to a building's overall stability and longevity. By selecting high-quality bricks according to these specifications, you enhance the structural integrity and resilience of your construction projects.

Efficient Space Utilization

Efficient space utilization is a critical standard when evaluating brick construction, as it significantly impacts design flexibility. With a standard brick size of approximately 7.5 inches by 3.5 inches by 2.25 inches, you can optimally achieve load-bearing efficiency while minimizing waste. Employing modular brick patterns can enhance structural integrity and aesthetic appeal without compromising usable space. By integrating bricks with high thermal mass, energy efficiency improves, contributing to longer-term sustainability in building projects.

Modular Design Compatibility

The standardization of brick dimensions typically follows a modular design approach, which enhances compatibility across various construction projects. Most commonly, bricks measure 7.5 inches in length, 3.5 inches in height, and 2.25 inches in thickness, allowing for easy integration with other building materials. This modularity facilitates efficient assembly, reduces waste, and promotes structural integrity in walls. By leveraging standardized brick sizes, you can streamline your construction process while ensuring architectural flexibility.

Economical Construction Cost

The standard of brick used in economical construction is typically measured by its compressive strength, defined as 3,000 psi or higher, facilitating durability while keeping costs low. Average brick prices can range from $0.50 to $2.00 each, impacting overall project budgets significantly. Utilizing 1,000 bricks can reduce wall construction costs to approximately $1,500 for materials alone. When selecting bricks for cost-effective designs, consider energy efficiency ratings, as they can yield savings on heating and cooling, enhancing long-term value.

Ease Of Transportation

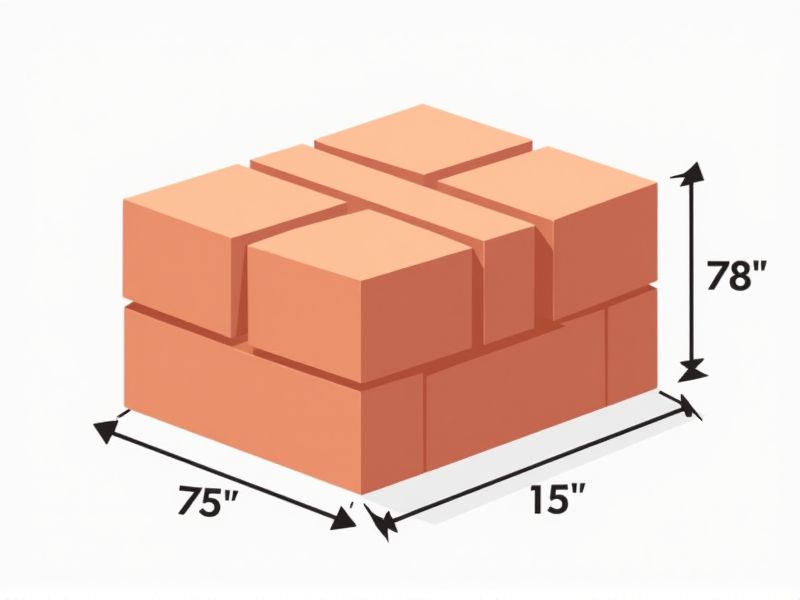

The standard of brick, particularly in construction, emphasizes ease of transportation, with many modern bricks designed to be lightweight yet durable. Standard dimensions typically measure 7.5 inches long, 3.5 inches wide, and 2.25 inches high, allowing for efficient stacking and loading onto vehicles. Many manufacturers produce bricks with a reduced weight of approximately 3 to 5 pounds each, facilitating easier handling by laborers during transport. Enhanced packing methods can increase shipment efficiency, reducing travel costs and enabling quicker delivery to construction sites, ultimately benefiting your project timeline.

Simplified Masonry Work

The standard size of a brick used in simplified masonry work is typically 7.5 inches long, 3.5 inches wide, and 2.25 inches high. This dimension provides optimal strength and durability, catering to various construction needs while maintaining a lightweight structure. When constructing walls, a standard mortar joint of approximately 0.5 inches is utilized, contributing to both structural integrity and aesthetic appeal. For effective insulation and energy efficiency, ensure your masonry project incorporates a well-structured plan for weather-resistant barriers.

Uniformity In Production

The production of standard bricks emphasizes the critical aspect of uniformity, ensuring each brick is manufactured to precise dimensions and specifications, typically measuring 7.5 inches by 3.5 inches by 2.25 inches. This consistency in size not only optimizes the strength and durability of structures but also simplifies the construction process, enabling faster assembly and reducing material waste. Implementing advanced quality control measures during production minimizes variations and guarantees compliance with industry standards, such as ASTM C62 and ASTM C216. When selecting bricks for your project, prioritize those from manufacturers that demonstrate a commitment to uniformity, ensuring reliable performance and aesthetic appeal in your construction.

Aesthetic Harmony

Aesthetic harmony in brick standards emphasizes the visual appeal and coherence of architectural designs. High-quality bricks, often measuring 7.5 x 3.5 x 2.5 inches, come in various colors and textures, allowing architects to create striking facades that blend with their surroundings. The use of standardized dimensions ensures uniformity in construction, facilitating easier installation while maintaining an elegant look. By selecting bricks that align with your design vision, you can achieve a balanced and aesthetically pleasing environment that resonates with both modern and traditional influences.

Quality Control Assurance

Quality control assurance in brick manufacturing involves rigorous testing processes to maintain a standard of excellence. Each batch of bricks undergoes inspections for dimensions, compressive strength, and resistance to weathering, ensuring durability and reliability. Compliance with industry standards such as ASTM C62 for clay bricks is essential for performance. By focusing on these quality metrics, manufacturers can offer bricks that not only meet construction requirements but also enhance the longevity of your structures.