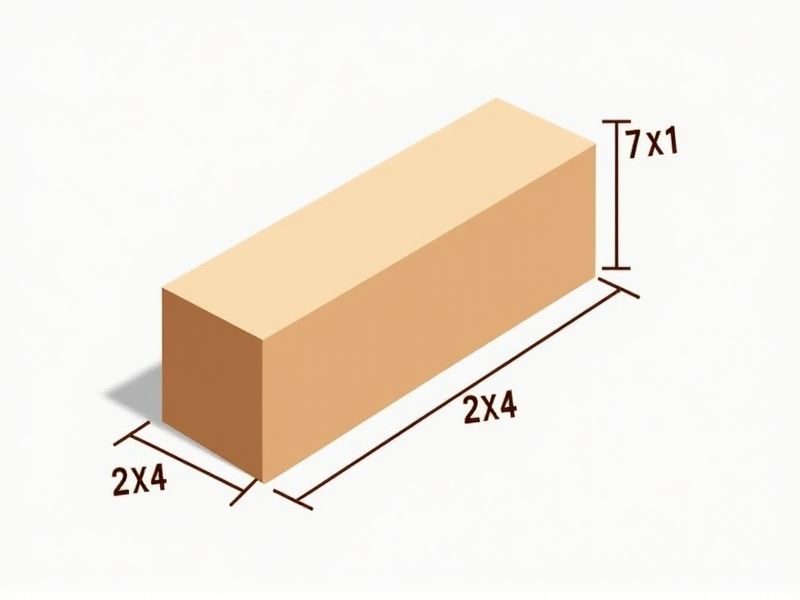

When someone refers to a "2x4" piece of lumber, they're using the nominal size, which isn't the actual measured size of the board. After the wood is dried and planed smooth, its actual dimensions are typically 1.5 inches thick by 3.5 inches wide. Knowing this distinction is particularly helpful when planning construction projects, as using the nominal measurements can result in errors in fitting or design. Always check and use the actual lumber dimensions for precise building and accurate material estimates.

Actual Size: 1.5 Inches By 3.5 Inches

When purchasing standard 2x4 lumber, it's essential to know that the actual dimensions are 1.5 inches by 3.5 inches. This size discrepancy is due to the milling process, where the lumber is planed to create a smooth finish. Understanding these measurements is crucial for effective project planning, ensuring that your calculations for framing, shelving, or other construction needs are accurate. When selecting your lumber, keep in mind that these actual dimensions impact the structural integrity and load-bearing capacity of your projects.

Nominal Size Discrepancy

When purchasing 2x4 lumber, it's important to note that the nominal size is different from the actual dimensions. The nominal measurement refers to the rough-cut size, which is 2 inches by 4 inches. However, after the milling process, the actual size typically measures 1.5 inches by 3.5 inches. Understanding this discrepancy can help you accurately plan your projects and ensure a proper fit in construction tasks.

Rough Vs. Finished Dimensions

2x4 lumber is categorized into rough and finished dimensions, impacting your construction projects significantly. The rough dimension measures approximately 2 inches by 4 inches before drying and planing, resulting in the finished size being about 1.5 inches by 3.5 inches. This reduction occurs due to the milling process that smoothens the surfaces for better fit and appearance in building applications. Understanding these measurements is crucial for ensuring accurate framing and structural integrity in your woodworking endeavors.

Industry-Standard Size

The industry-standard size for 2x4 lumber measures approximately 1.5 inches in thickness and 3.5 inches in width, with the nominal dimensions of 2 inches by 4 inches being derived from its rough-sawn state before drying and planing. This dimensional lumber is primarily utilized for framing and structural applications, making it a staple in construction projects. When selecting 2x4s, it's essential to consider the grade, which ranges from Select Structural to Standard, as this affects both strength and appearance. Your choice of lumber should also comply with local building codes, ensuring safety and durability in your construction endeavors.

Shrinkage During Drying

The standard 2x4 lumber, commonly used in construction, typically experiences a shrinkage rate ranging from 6% to 10% during the drying process. This shrinkage is primarily due to the loss of moisture content as the wood transitions from green to kiln-dried. As a 2x4 board dries, you may notice a reduction in both width and thickness, which can affect structural integrity and alignment in your projects. Understanding this shrinkage is essential for ensuring proper fit and finish in applications such as framing and cabinetry.

Common Construction Use

2x4 lumber is commonly employed in construction for framing walls, floors, and roofs, providing structural support with a nominal measurement of 1.5 inches by 3.5 inches after drying and planing. Typically made from softwood species like spruce, pine, or fir, a standard 2x4 is available in various lengths, with 8-foot being the most prevalent. It's essential for you to consider the grade of the lumber, as it affects strength and appearance; options include standard grades like No. 1 and No. 2, which indicate quality and potential applications. The conventional load-bearing capacity of a 2x4 can support up to 1,000 pounds when properly installed and spaced, making it a reliable choice for residential and commercial construction projects.

Framing Applications

2x4 lumber is the industry standard for framing applications in residential construction, providing optimal strength and durability. Typically made from softwood species like pine, fir, or spruce, a standard 2x4 measures 1.5 inches by 3.5 inches in actual dimensions. This versatile lumber can support loads effectively, with a typical allowable bending stress of 1,200 psi, making it suitable for walls, roofing, and floor systems. When planning your framing projects, account for local building codes and standard lengths, usually 8, 10, or 12 feet, to ensure structural integrity and compliance.

Planing Process

The planing process for standard 2x4 lumber involves reducing the thickness of the wood to a finished size of 1.5 inches by 3.5 inches, adhering to the nominal designation. This procedure is crucial for achieving a smooth surface, eliminating roughness, and ensuring uniform thickness across the board, which drastically affects both aesthetics and structural integrity. During planing, the wood is typically fed through a thickness planer that removes a specific amount of material, often around 1/16 to 1/8 inch at a time, depending on the initial surface condition. Properly planed 2x4 lumber surfaces enhance paint adhesion and facilitate a more professional finish in construction and cabinetry projects.

Cost Considerations

The average cost of 2x4 lumber fluctuates around $3.50 to $6.00 per board, significantly influenced by market demand and geographic location. On a project scale, using 2x4s can account for 30-40% of your total material cost, making careful selection crucial. When purchasing in bulk, you might find discounts ranging from 10% to 20%, helping to lower overall expenses on larger constructions. You should also consider the long-term implications of your choice, as treated versus untreated lumber variations can impact both immediate costs and future maintenance.

Availability In Lengths

2x4 lumber commonly comes in various lengths to accommodate diverse construction needs, with standard offerings ranging from 8 to 16 feet. The most widely used length is 8 feet, making up approximately 30% of total sales, followed closely by 10-foot lengths. Availability may vary by region but most suppliers maintain consistent stock of these popular sizes due to high demand in framing and structural projects. For your project, selecting the appropriate length can minimize cuts and waste, ultimately saving time and cost.